I-Intelligent Mixing and Batching System ye-Powder Materials

Ividiyo

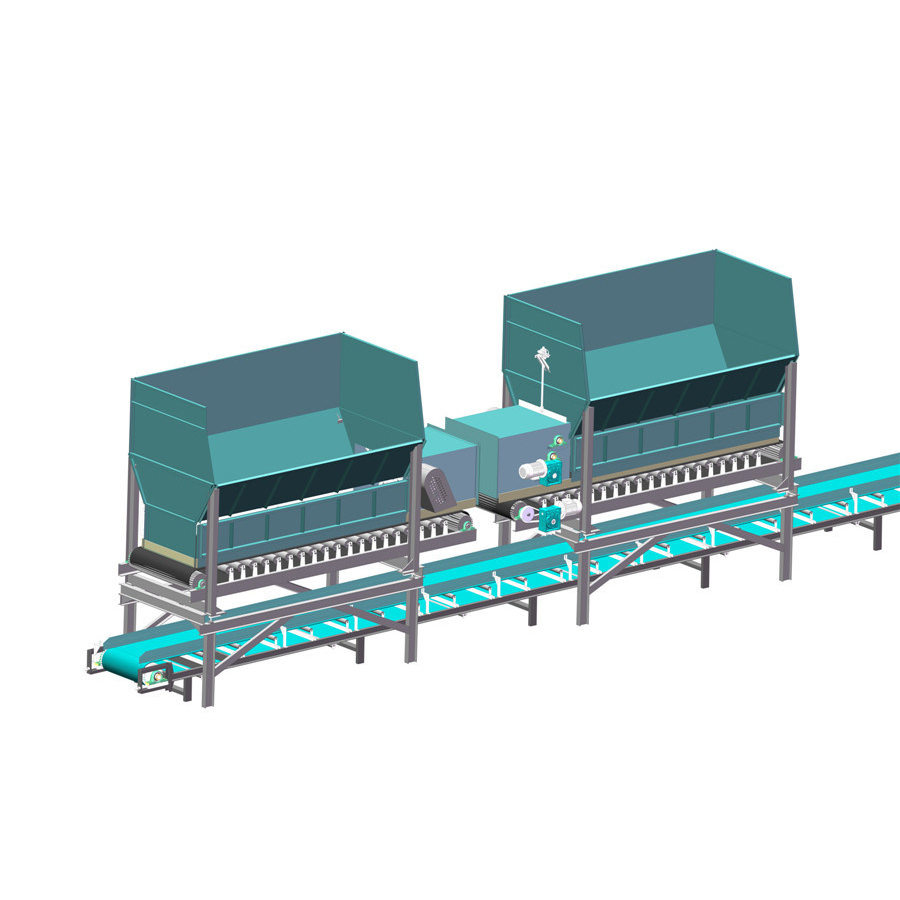

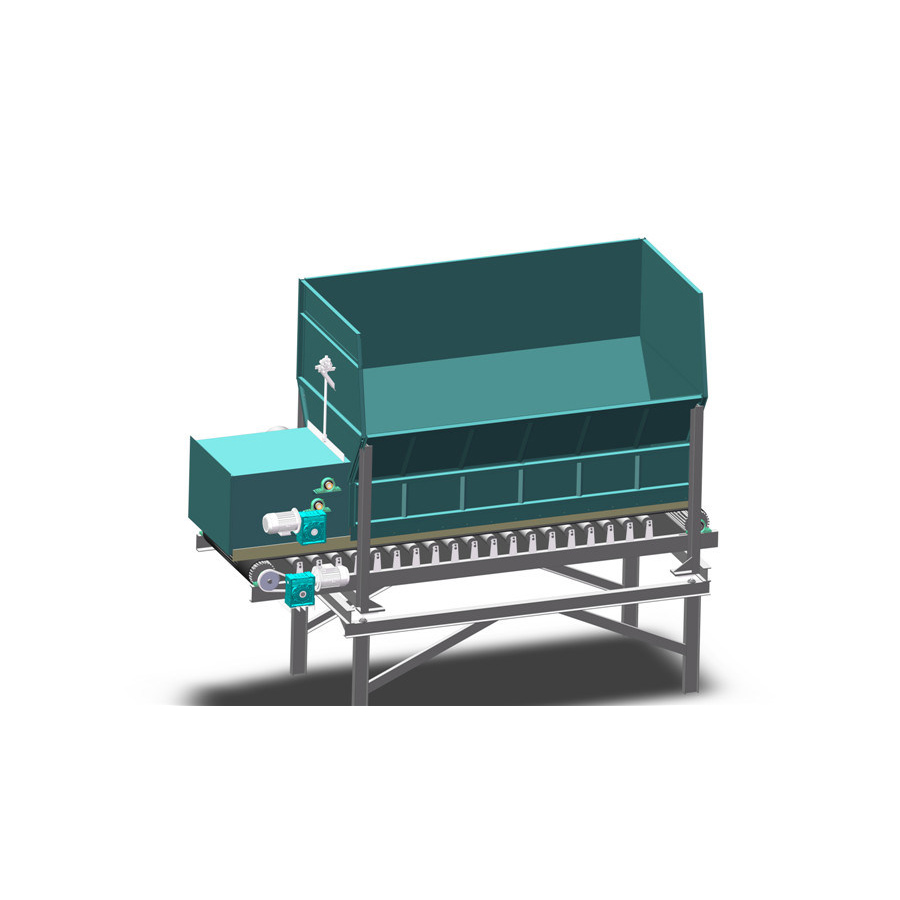

Incazelo Yesikalo Sokudla Kwe-Hopper

Sethula isikali esisha sokuphakela i-hopper, isengezo sakamuva kulayini wethu womkhiqizo!

Isikali sethu sokuphakela i-hopper siklanywe ngokunemba nokusebenza kahle engqondweni, ikakhulukazi izimboni ezifana nezolimo, ukukhiqiza ukudla, nokucubungula amakhemikhali.Isikali siyakwazi ukukala ngokunembile futhi sikhiphe izinhlobo ezihlukahlukene zezinto zokwakha, kusukela kuzimpushana nama-granules kuya kumbewu noketshezi.

Esinye sezici ezibalulekile zesikali sethu sokuphakela i-hopper umthamo wayo omkhulu we-hopper, ovumela abasebenzisi ukuthi bafake inani elikhulu lezinto ngesikhathi esisodwa, ukunciphisa isidingo sokugcwalisa kaningi futhi kuthuthukiswe ukusebenza kahle komsebenzi wonke.I-hopper yakhelwe ukuthi ibe uthuli-ubufakazi, ukuqinisekisa ukuthi impahla ekalayo ihlala ihlanzekile futhi ihlanzekile kuyo yonke inqubo.

Isisindo esinembile nesithembekile sibalulekile ezimbonini eziningi, futhi isikali sethu sokuphakela i-hopper siletha lokho kanye.Ifakwe amaseli omthwalo anembe kakhulu, okuvumela ukufundwa okunembile ngisho nangezinto zokuminyana ezihlukene.Izinga lokubekezelela isikali liyalungiseka, okulenza lifanelekele ukusetshenziswa nezinto ezinokuminyana okuhlukile noma izici zokugeleza.

Ngaphezu kokunemba kwayo, isikali sethu sokuphakela i-hopper sibuye sisebenziseke kalula futhi sisebenziseka kalula.Iza ifakwe iphaneli yokulawula esebenziseka kalula kanye nesixhumi esibonakalayo esinembile esivumela abasebenzisi ukuthi baphathe izilungiselelo nemisebenzi yesikali kalula.Isilinganiso sibonisa ukukhishwa kwezinto ezizenzakalelayo, sisusa isidingo sokungenelela okwenziwa ngesandla kanye nokwenza lula inqubo yokukala.

Ngaphezu kwalokho, isikali sethu sokuphakela i-hopper siklanywe ngokuhlala isikhathi eside nempilo ende engqondweni.Yenziwe ngezinto ezisezingeni eliphezulu, iqinisekisa ukuthi ingamelana nokusetshenziswa njalo kanye nokuchayeka ezimeni ezinzima.Isikali siphinde sibe ne-anti-corrosion coating ethuthukisiwe, evikela umswakama kanye nomonakalo wokugqwala, okuqinisekisa isikhathi eside sokuphila.

Ukuguquguquka kwesikali sokuphakelayo kwe-hopper kuyenza ifaneleke ukusetshenziswa ezinhlobonhlobo zezimboni, okuhlanganisa izimboni zezimayini, zamakhemikhali, nezemithi, phakathi kwezinye.Ingalungiswa ukuze ihambisane nezidingo ezithile zohlelo lokusebenza, futhi iyakwazi ukuphatha imisebenzi yokukhiqiza emincane nemikhulu.

Isilinganiso sokuphakelayo se-hopper siza nokusekelwa kwamakhasimende okuzinikele, imanuwali egcwele yomsebenzisi, nezinto zokuqeqesha, eziqinisekisa ukuthi bonke abasebenzisi bangasebenzisa ngokugcwele amakhono abo.

OIsikali sokuphakelayo se-ur hopper siyisixazululo esiqanjwe kabusha nesithembekile esenzelwe ukukala nokusatshalaliswa kwezinhlobonhlobo zezinto.Ukunemba kwayo, ukuqina, kanye nokusebenziseka kalula kwayo kuyenza ibe isengezo esihle kunoma iyiphi inqubo yokukhiqiza, ukuthuthukisa ukusebenza kahle, nokunciphisa izindleko.Xhumana nathi namuhla ukuze ufunde kabanzi mayelana nokuthi umkhiqizo wethu ungashintsha kanjani ukusebenza kwakho!

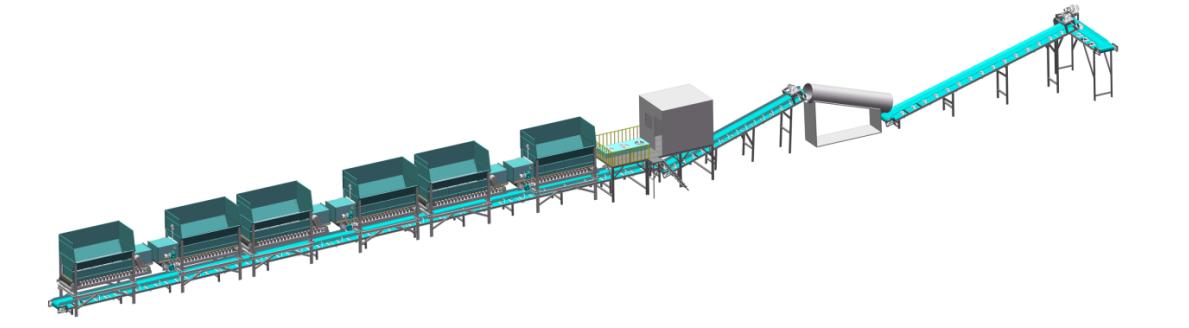

Imisebenzi yesistimu yokuhlanganisa ehlakaniphile

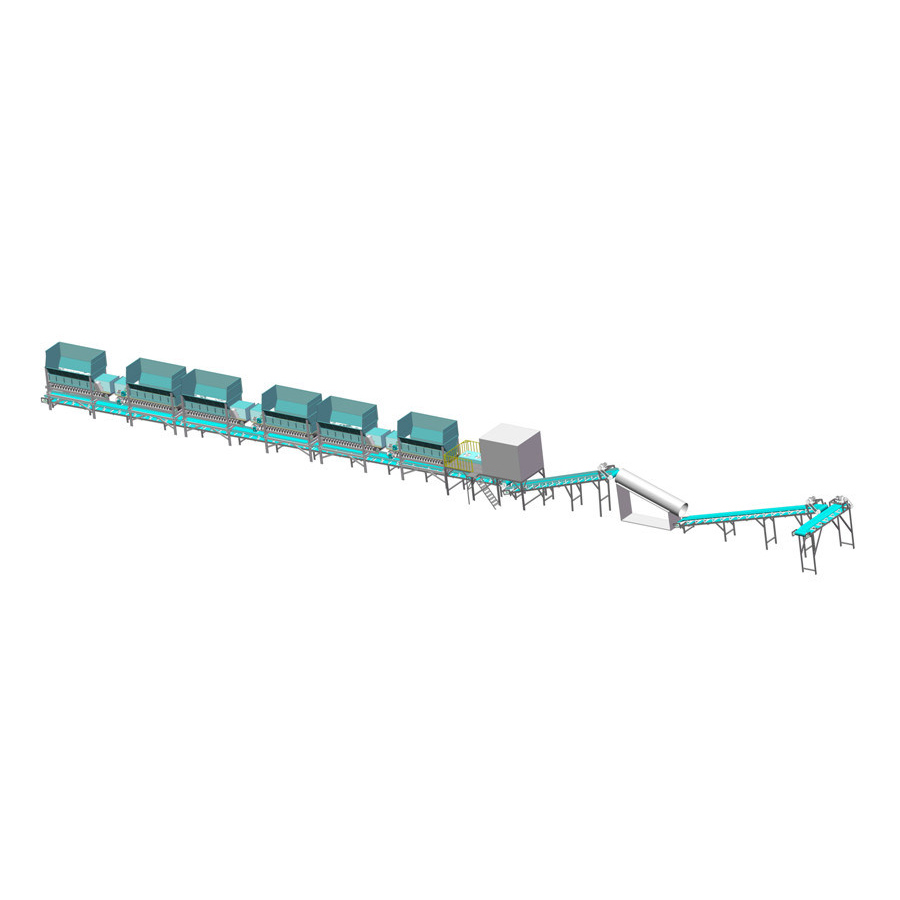

1. Uhlelo lokuhlanganisa lwe-Wang Gong Weighing feeder lungahlangabezana nezidingo zokuhlanganisa zezinhlobo ezahlukene zezinto zokusetshenziswa zokukhiqiza, futhi lungalungiswa ngokuphakelayo okuningi, okulula ukukuqala, ukusebenza kahle okuphezulu, ukuphuma okuphezulu, nezinto ezinhle.

2.Adopt isibonisi sesikrini sokuthinta kanye nokulawula ukusebenza kwenkinobho.Isisindo sempahla yesikhathi sangempela nesimo sokusebenza sesiphakeli ngasinye siboniswa esikrinini sokuthinta ngesikhathi sangempela, kanye nesimo sokusebenza sesithuthi ngasinye.Inani eliqondiwe lempahla yefomula ekhethiwe, umswakama (umswakama ungashintshwa), ubuningi besikhathi sangempela.

I-3.Imodi yokulawula uhlelo lokuphakelayo ihlukaniswe ngemodi ezenzakalelayo ngokugcwele kanye nemodi yezandla

4. Isikrini sedijithali sibonisa isisindo sento ekuphakeleni ngesikhathi sangempela, futhi isikhathi sokuma semodi yomjikelezo kumodi ezenzakalelayo siboniswa ngokubala wehle kwesikrini sedijithali.Ukuboniswa kwesikrini sedijithali "-------" lapho i-feed ingadingi ukwenza umsebenzi wokupheka.

5.Isilawuli se-Conveyor: Uma imodi ye-conveyor yokuphakela ngokuzenzekelayo, ngemva kokuba isiphakeli sesiqedile ukuphakela ngesikhathi esisodwa, umthumeli udinga ukubambezela ukulethwa kwezinto zomthumeli ekamelweni lokuxutshwa.

I-6.I-feeder ifakwe i-infrared grating, futhi ukulayishwa kwe-forklift kuthinta umugqa wokugaya lapho imodi ezenzakalelayo idla, futhi wonke umugqa uyaqhubeka nokusebenza ngokuzenzakalelayo lapho umlayishi ephuma ngemva kokulayisha.

7.Ihlinzeka ngokukhishwa kokushintsha ekuqaleni kwe-batching kanye nokukhishwa kokushintsha ekupheleni kokuhlanganiswa

8.Lapho i-feeder ingaphansi kwesisindo esithile, wonke ulayini uyayeka ngokuzenzakalelayo ukuphakela futhi uxwayise ngokukhanya kwe-alamu.

9.Isitoreji sefomula 10, idatha yokondla igcinwa okungenani inyanga eyodwa, ugesi ucisha futhi iphutha lirekhoda isisindo sokudla.

Inzuzo Yesistimu

1: Uhlelo lokuhlanganisa oluzenzakalelayo lwamukela isilawuli esihlelekayo kanye nekhompuyutha yezimboni njengomongo, osayizi omncane, ophakeme ngokunemba futhi omuhle ekuzinzeni.

2: Uhlelo lokuhlanganisa oluzenzakalelayo lungalawula izikali eziningi, izinto ezihlukahlukene ezihlukene noma ukulawula ukuphuma ngesikhathi esisodwa (kuye ngokuthi inqubo)

I-3: Ukulawula okuhlakaniphile kwesikhathi sokuxubha, akukho ukulinda phakathi kwezikali zesithako, ukuze umjikelezo wokuhlanganisa ufinyezwe, uthuthukise isivinini sokuxubha nokuphuma.

I-4: Isistimu ye-batching ezenzakalelayo yamukela isiteji sesistimu yakamuva, egijima ngokushesha futhi ezinzile, isikrini sokukhiqiza esiguqukayo sesikhathi sangempela, esibonisa inqubo yokukhiqiza, ukusebenza okunembile, umsebenzi wokubuyisela ocacile nokuzenzakalelayo.

5: Uhlelo lokuhlanganisa oluzenzakalelayo lunomsebenzi wokubika onamandla, lungarekhoda futhi lugcine izinhlobo ezahlukene zedatha nokuphrinta kwetafula ngobuningi, luhlanganise ngokuzenzakalelayo futhi luphrinte umbiko wesithako ngemva kokuqedwa kokukhiqizwa ngakunye, futhi lunikeze usuku, isikhathi, inombolo yombiko kanye nokwangempela. ukusetshenziswa kwempahla ngayinye;ukukhishwa kombiko kusebenzisa indlela yombuzo we-PC manual, futhi umbiko wokugcina wokukhiqiza ugcinwa ngaphakathi kwekhompyutha, ongafundwa unomphela ukuze kuqinisekiswe ukulunga nobuqotho bombiko wokukhiqiza.

I-6: Ukusebenza okulula, uhlelo lunezindlela zokukhiqiza ezintathu ezizenzakalelayo, ze-semi-automatic.

I-7: Ikhono eliqinile lokucubungula idatha, izinga lesampula elisheshayo nelizinzile, inqubo yokuhlanganisa ingahlangabezana ngokugcwele nezidingo zenqubo yokuhlanganisa.

I-8: Inqubo ye-batching system ezenzakalelayo ingasethwa ngokusho komsebenzisi.

I-9: ukwethembeka okuhle, uhlelo lwe-automatic batching system lunezinhlelo ezimbili zokulawula (isikrini sokuthinta kanye nohlelo lwekhompyutha yezimboni) Uma enye yezinhlobo zakwamanye amazwe inephutha, enye inqamula ukusebenza ngokushesha ngaphandle kokuthinta ukukhiqizwa, futhi uhlelo lokuhlanganisa oluzenzakalelayo lungaqeda ukukhiqizwa okuphunyukayo lapho kwenzeka ukwehluleka kokukhiqiza.

I-10: Uhlelo lwe-batching oluzenzakalelayo lubonisa inqubo yokukhiqiza ngesikhathi sangempela futhi umbhalo ubonisa inqubo yokukhiqiza, elula ukuthi opharetha asebenze.

11: Ifayela lombhalo lesistimu yokuhlanganiswa okuzenzakalelayo libonisa imibiko yokukhiqiza, imibiko yeresiphi, njll. (kunenombolo yokuqukethwe okuphrintiwe okukhethwe umsebenzisi) Umsebenzi onamandla wokwazisa i-alamu, onganciphisa izinga lokulahlwa libe ubuncane

12: Ukufana kwesistimu yokuhlanganiswa okuzenzakalelayo, isikhathi ngasinye sokukhululwa esihlanganisiwe sisebenzisa isiguquli semvamisa ukulawula isivinini sokukhipha ukuze iqoqo ngalinye ngesikhathi esifanayo likhulule, ukuze kuqinisekiswe ukufana kokuhlanganisa.

13: I-automatic batching system online automatic monitoring system: ubudlelwano phakathi kwabantu kanye nolayini wokukhiqiza ukusuka ku-passive kuya kokusebenzayo, uma sekwenziwe izimo ezingajwayelekile, uhlelo lwekhompiyutha ngokushesha luthatha isinyathelo sokuthumela i-alamu kubasebenzi abafanelekile, thatha isinyathelo yenza umsebenzi wesikhumbuzi, ngokusebenzisa imonitha ye-inthanethi yesikhathi sangempela, qapha imininingwane ebalulekile yokukhiqiza nganoma yisiphi isikhathi

Indlela izinto zokuhlanganisa zisebenza ngayo

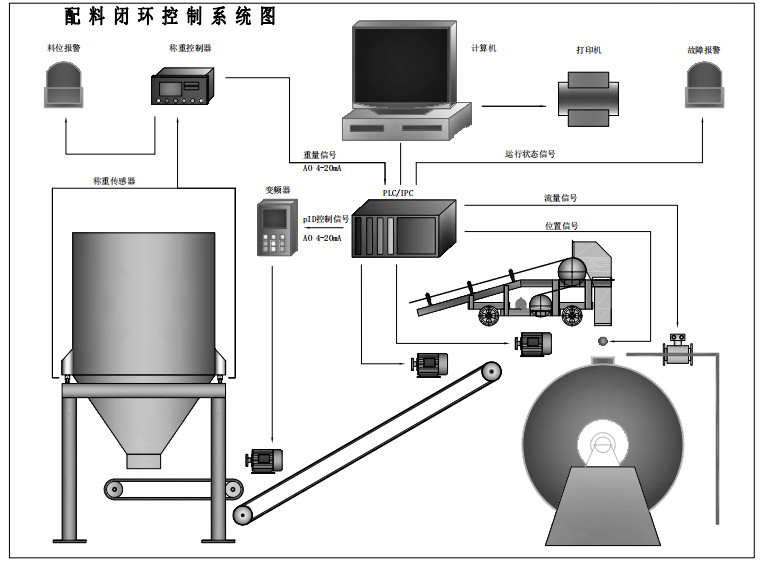

Isibonelo, i-automatic batching system yenziwe ngemigqa emi-5 yokuhlanganisa ibhande le-elekthronikhi, enombolo 1#, 2#, 3#, 4#, 5#, okuthi 1# ~ 4# iyiqembu, 1# iyinto esemqoka. isikali, kanti ezintathu ezisele ziyizikali zezinto ezisizayo.Uma singekho isidingo sokwengeza abasizi, isikali sikagesi esingu-5# sisebenza sodwa ukuze sidlulise okubalulekile.Uhlelo lunemisebenzi emibili: ukugeleza njalo kanye nokulawula isilinganiso.Ukulawulwa kokugeleza okuqhubekayo, isikali sebhande le-elekthronikhi silungisa ngokuzenzakalelayo isivinini sebhande ngokuvumelana nenani lezinto ezisebhande ukuze kuhlangatshezwane nezidingo zokugeleza ezimisiwe.Ukugeleza kwenqubo yesistimu yesikali esikhulu (1#) kuyahlaziywa, futhi ukugeleza kwenqubo kuboniswa kuMfanekiso 1.

Ngemuva kokuthi isistimu ye-batching ezenzakalelayo ivuliwe, injini ye-belt drive motor iqala ukujikeleza, futhi i-microprocessor ilawula isivinini semoto ngokuya ngokusebenza kwamanje.Izinto eziku-hopper ziwela endaweni engenalutho futhi zithuthwa ngebhande endaweni yokukala, lapho izinto ezisebhande zikalwa ngesilinganiso sebhande le-electronic.Iseli lomthwalo likhipha isignali ye-voltage ngokusekelwe kubukhulu bamandla, akhuliswa isidlulisi ukuze kukhishwe isignali yezinga lemitha ngokulingana nesisindo sento.Isignali ithunyelwa kusixhumi esibonakalayo sekhompuyutha yokusingatha, isampuliwe futhi iguqulelwe isignali yethrafikhi, futhi inani lamanje lokugeleza liboniswa kukhompuyutha yokusingatha.Ngasikhathi sinye, lesi siginali yokugeleza ithunyelwa kusixhumi esibonakalayo se-PLC, uma kuqhathaniswa nezithako ezahlukahlukene ezishiwo yikhompuyutha yokusingatha, bese kwenziwa umsebenzi wokulungisa, futhi inani lokulawula lithunyelwa kusiguquli semvamisa ukuze kushintshwe inani lokukhiphayo. i-converter frequency, ngaleyo ndlela ishintsha isivinini semoto yokushayela.Lungisa umthamo ukuze ulingane nenani elimisiwe ukuze uqedele inqubo yokuhlanganisa okuzenzakalelayo.

Ukulungiselelwa kwepharamitha

| Amakhono okuhlanganisa aklama | 0~120t/h |

| Ukunemba kwesisindo sodwa | 1/1000 |

| Ukunemba kwesistimu yokuhlanganisa | 2/1000 |

| Ukulinganisa ukulungisa ukunemba | 1/1000 |

| Usayizi wezinhlayiyana zezinto | ≤100mm(Ubude obukhulu be-diagonal) |

| Okuqukethwe umswakama wento | ≤10% |

| Imodi yokulawula isistimu | okumaphakathi, ukulawula endaweni |

| Sebenzisa izinga lokushisa le-ambient | -10℃~+45℃ |

| Sebenzisa umswakama olinganiselwe | ≤90%RH |

| I-voltage yegridi yesistimu | 380V±10%220V±10%;50Hz |

| Amandla kagesi | ≤200kw |

| Imodi yesistimu yokusebenza | Okuqhubekayo |

Izimfuno zemakethe

Izithako kuyinqubo ebaluleke kakhulu ekukhiqizeni amabhizinisi ezimboni, ikhwalithi, ukusebenza kahle kanye nokuzinza kwenqubo yokuhlanganisa idlala indima ebalulekile kuyo yonke inqubo yokukhiqiza yezimboni kanye nekhwalithi yomkhiqizo, uhlelo lwesithako olubuyela emuva alusebenzi nje kuphela futhi. ukusebenza okungalungile, okwenziwe ngesandla kwezithako kanye nokwethulwa kwezinto zomuntu kusixhumanisi sokuhlanganisa, okuthinta kakhulu ukuzinza nokuthuthukiswa okuqhubekayo kwekhwalithi yomkhiqizo, futhi kunomsebenzi omkhulu, ukuntuleka kokuvikelwa kwabasebenzi, ukuvikelwa kwemvelo akufinyeleleki ezingeni kanye nezinye iziphambeko. , Izithako ezenziwe ngezandla zenza kube nzima ukuthi ukwakheka kwezimboni kubonakale ekukhiqizeni kwezimboni ezinkulu.Ngakho-ke, ukunemba okuphezulu kanye nezinhlelo zokuhlanganisa ezihlakaniphile zibaluleke kakhulu emabhizinisini ezimboni.

Iqhaza elibalulekile "lemboni yokukhiqiza emhlabeni wonke" ekhula ngokushesha yaseChina kanye nemboni yezinhlelo zokuhlanganisa ezihlakaniphile ezisahlehle emuva kuye kwakha ukungqubuzana okukhulu namathuba emakethe, okwenza imakethe yezinhlelo ze-batching ezihlakaniphile yasekhaya ibe yimakethe encintisanayo emhlabeni wonke, kodwa futhi iheha ukungena kwezimali zasekhaya. ukwanda kokutshalwa kwezimali embonini yezithako ezihlakaniphile zezimboni, futhi kwavula imakethe yasekhaya.

Ubuchwepheshe bokulawula ukuhlanganisa okuhlakaniphile busetshenziswa kabanzi njengobuchwepheshe bokulawula ugesi, ubuchwepheshe bokulinganisa, ubuchwepheshe bezinzwa, ubuchwepheshe besoftware yekhompiyutha, ubuchwepheshe bemishini, izinto zokwakha kanye nobuchwepheshe bamakhemikhali nobunye ubuchwepheshe obuhlukahlukene obuhlukahlukene, ubuchwepheshe obunobungcweti obuhlukahlukene, ubuchwepheshe bokulawula ukuxubha obuhlakaniphile busetshenziswa kakhulu amabhizinisi okukhiqiza izimboni izinto zokusetshenziswa, ukulinganisa izinto ezisizayo, ezokuthutha, isitoreji kanye nokudla kanye nezinye izici zesixhumanisi.

Amacala wokufaka izicelo

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

Whatsapp

-

I-WeChat