I-Automatic Hopper Weighing Scale Sezinto Eziningi

Ividiyo

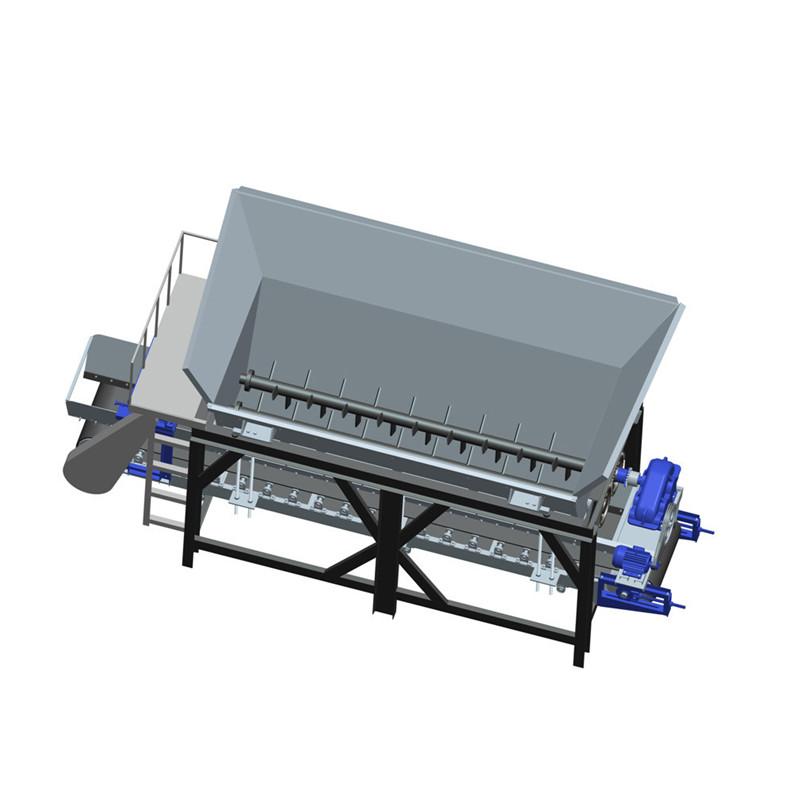

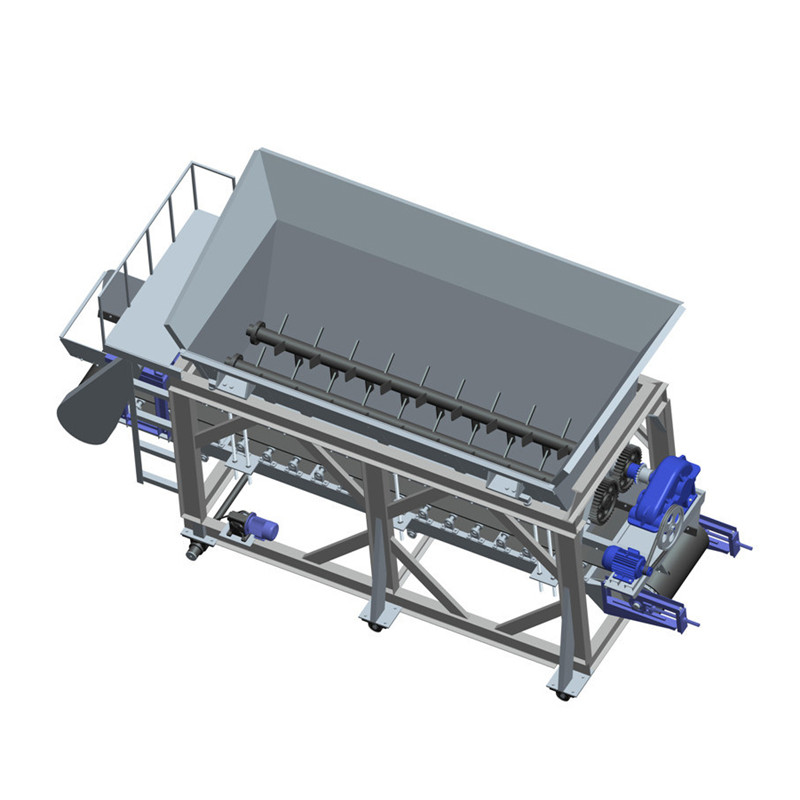

Incazelo Yesikali Sokuncelisa I-Hopper

Sethula isikali esisha sokuphakela i-hopper, isengezo sakamuva kulayini wethu womkhiqizo!

Isikali sethu sokuphakela i-hopper siklanywe ngokunemba nokusebenza kahle engqondweni, ikakhulukazi izimboni ezifana nezolimo, ukukhiqiza ukudla, nokucubungula amakhemikhali.Isikali siyakwazi ukukala ngokunembile futhi sikhiphe izinhlobo ezihlukahlukene zezinto zokwakha, kusukela kuzimpushana nama-granules kuya kumbewu noketshezi.

Esinye sezici ezibalulekile zesikali sethu sokuphakela i-hopper umthamo wayo omkhulu we-hopper, ovumela abasebenzisi ukuthi bafake inani elikhulu lezinto ngesikhathi esisodwa, ukunciphisa isidingo sokugcwalisa kaningi futhi kuthuthukiswe ukusebenza kahle komsebenzi wonke.I-hopper yakhelwe ukuthi ibe uthuli-ubufakazi, ukuqinisekisa ukuthi impahla ekalayo ihlala ihlanzekile futhi ihlanzekile kuyo yonke inqubo.

Isisindo esinembile nesithembekile sibalulekile ezimbonini eziningi, futhi isikali sethu sokuphakela i-hopper siletha lokho kanye.Ifakwe amaseli omthwalo anembe kakhulu, okuvumela ukufundwa okunembile ngisho nangezinto zokuminyana ezihlukene.Izinga lokubekezelela isikali liyalungiseka, okulenza lifanelekele ukusetshenziswa nezinto ezinokuminyana okuhlukile noma izici zokugeleza.

Ngaphezu kokunemba kwayo, isikali sethu sokuphakela i-hopper sibuye sisebenziseke kalula futhi sisebenziseka kalula.Iza ifakwe iphaneli yokulawula esebenziseka kalula kanye nesixhumi esibonakalayo esinembile esivumela abasebenzisi ukuthi baphathe izilungiselelo nemisebenzi yesikali kalula.Isilinganiso sibonisa ukukhishwa kwezinto ezizenzakalelayo, sisusa isidingo sokungenelela okwenziwa ngesandla kanye nokwenza lula inqubo yokukala.

Ngaphezu kwalokho, isikali sethu sokuphakela i-hopper siklanywe ngokuhlala isikhathi eside nempilo ende engqondweni.Yenziwe ngezinto ezisezingeni eliphezulu, iqinisekisa ukuthi ingamelana nokusetshenziswa njalo kanye nokuchayeka ezimeni ezinzima.Isikali sibuye sibe ne-anti-corrosion coating ethuthukisiwe, evikela umswakama kanye nokulimala kokugqwala, okuqinisekisa impilo ende.

Ukuguquguquka kwesikali sokuphakelayo kwe-hopper kuyenza ifaneleke ukusetshenziswa ezinhlobonhlobo zezimboni, okuhlanganisa izimboni zezimayini, zamakhemikhali, nezemithi, phakathi kwezinye.Ingalungiswa ukuze ihambisane nezidingo ezithile zohlelo lokusebenza, futhi iyakwazi ukuphatha imisebenzi yokukhiqiza emincane nemikhulu.

Isilinganiso sokuphakelayo se-hopper siza nokusekelwa kwamakhasimende okuzinikele, imanuwali egcwele yomsebenzisi, nezinto zokuqeqesha, eziqinisekisa ukuthi bonke abasebenzisi bangasebenzisa ngokugcwele amakhono abo.

OIsikali sokuphakelayo se-ur hopper siyisixazululo esiqanjiwe nesithembekile esiklanyelwe ukukala nokusatshalaliswa kwezinhlobonhlobo zezinto.Ukunemba kwayo, ukuqina, kanye nokusebenziseka kalula kwayo kuyenza ibe isengezo esihle kunoma iyiphi inqubo yokukhiqiza, ukuthuthukisa ukusebenza kahle, nokunciphisa izindleko.Xhumana nathi namuhla ukuze ufunde kabanzi mayelana nokuthi umkhiqizo wethu ungashintsha kanjani ukusebenza kwakho!

Incazelo

1. Lapho impahla idinga ukulayishwa, u-opharetha ukhetha ukuqala ifomula yokushaja, futhi isikrini se-LED sibonisa igama lempahla ekhethiwe yefomula, isisindo esidingekayo, isisindo esifakiwe, inombolo yokugaya ibhola ehambisanayo, ukubekezelela. inani, isisindo esifakiwe, kanye nesibani esiyisixwayiso sezendlalelo eziningi siluhlaza, okubonisa ukuthi ukushaja kungaqala;

2. Uma isisindo sezinto ezibonakalayo sifinyelela ku-90% wesisindo esidingekayo (singasethwa ngokwaso), ukukhanya okuphuzi kwesibani esiyisixwayiso se-multi-layer kukhanya, okukhumbuza umshayeli we-loader ukuba anciphise;

3. Uma isisindo sempahla sifinyelela isisindo esimisiwe sempahla, ukukhanya okuyisixwayiso kwezingqimba eziningi kubomvu.Khumbuza isilayishi ukuthi ukulayisha kufanele kumiswe;

4. Uma isisindo sokulayisha sidlula uhla olubekiwe, yenza kusebenze izibani ezixwayisayo zomsindo nezikhanyayo, utshele umlawuli ukuthi enze ukucubungula kokungenela mathupha, futhi angakhetha ukulayisha kabusha noma ukubonisa into elandelayo ngemva kokwelashwa mathupha;

5. Uma ukucushwa kwesisindo kungafaneleki, uhlelo ngeke lufeze ukulandelana kwe-batching okulandelayo, kanye ne-alamu yomsindo nokukhanya kuze kube yilapho abasebenzi sebecutshungulwa;

6. Lapho i-electronic scaler weight stability value itholakala imizuzwana emi-5 elandelanayo (ingasethwa ngokwayo) ngaphakathi kwevelu yokubekezelela, ukushaja kuyafaneleka, futhi uhlelo lubonisa into elandelayo, njengokuthi akukho lutho olulandelayo, olubonisa ukuqedwa kokulayisha. .

Ukuqinisekiswa kwemiphumela yeresiphi

Lapho zonke izinto ezikufomula zikalwa, uhlelo luzohlola futhi luqhathanise izisindo zezinto ezisefomula ngayinye ukuze kubonakale ukuthi isifinyezo sesisindo sihlangabezana yini nezidingo, futhi ngemva kwempumelelo, sigcinwa kudatha.

Idatha Yekhono

| Isiphakeli sebhande le-elekthronikhi (ukuxuba). | 10t | 15t | 20t | 40t | 60t | 80t |

| Ukwehlukana | 5kg | 5kg | 10kg | 20kg | 20kg | 20kg |

| Ubukhulu besisindo | 10t | 15t | 20t | 40t | 60t | 80t |

| Isisindo esincane | 50kg | 50kg | 100kg | 200kg | 200kg | 200kg |

| Izinombolo zokuhlukanisa | 2000n | 3000n | 2000n | 2000n | 3000n | 4000n |

| Isivinini sokudlulisa | 7.8m/min | 7.8m/min | 7.8m/min | 7.8m/min | 7.8m/min | 7.8m/min |

| Isamba senani lokudla kwe-hopper | 7 CBM | 10CBM | 14CBM | 28 CBM | 42 CBM | 56 CBM |

| Okuphumayo kwezinto | 100T | 100T | 100T | 100T | 100T | 100T |

| Izinto zensimbi | Q235 | Q235 | Q235 | Q235 | Q235 | Q235 |

imininingwane

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

Whatsapp

-

I-WeChat